Cases of VFD

Application of frequency Inverter in Paper Feeder Machine

1. Background

Printing machinery's processing objects include paper, cardboard, film of various thicknesses, as well as thinner metal materials and other substrates.

The printing equipment adopts various printing methods (convex, flat, concave, hole, special printing) according to the requirements of different printed materials, and accurately prints various colors on the prescribed position of the substrate according to the proportion, so as to form text, images, Colorful prints inside.

2. Process

Printing machinery is mainly divided into four main parts: paper feeding, printing, drying and stacking. In the process of processing, it is necessary to ensure that the printing material moves according to the specified requirements, and that the printing material must be printed in various colors or processed on the printing material during the travel of the printing material, resulting in the paper transfer movement of the printing machinery ) And printing movement (printing device) two movement chains. K20 series frequency inverter is mainly used for paper feeder, drag paper, and complete the feeding process.

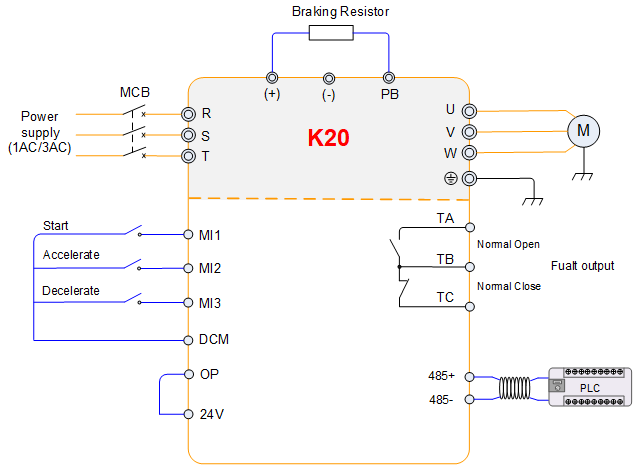

2.1 Braking method; when the printing work ends, various printing failures need to be stopped quickly.

2.2 Start-up mode; when the printing device is turned on, the speed is relatively low. The paper feeder can only be started after the printing press is running.

2.3 Constant speed mode; during work, the transmission speed of the paper feeder is changed by the plus and minus buttons.

2.4 Data upload; the parameters of the inverter need to be converted by PLC and then uploaded to the host computer.

3. Electrical control chart

4. Advantages

4.1 The frequency converter uses DC braking to decelerate and stop. When the operating frequency is 30HZ, the inverter applies direct current (30%) to the stator winding of the asynchronous motor, so that the motor stops quickly.

4.2 The frequency inverter uses terminal start and stop mode. The start-up signal of the paper feeder is taken as the start-up sign of the printing device, which can improve the finished product efficiency of the printing machine.

4.3 The frequency inverter is equipped with RS485 port as standard, which can upload data to PLC via MODBUS communication protocol. The printer can be controlled by PLC conversion, which can help the linkage between the paper feeder and the printer.