Transmitter

RZ13 Series Temperature Transmitter

Product Details

RZ13 series temperature transmitter is a kind of high precision, wide application range, direct output two-wire 4-20mA standard current signal, it is an industrial temperature measuring instrument with excellent cost performance.

The electrical housing of the RZ13 adopts a fully waterproof stainless steel. This ultra-micro structure integrated with a strong anti-interference signal conditioning circuit can reliably measure temperature for big vibration environment with strong reliability.

The RZ13 temperature transmitter uses high-reliability and long-life imported Class A PT100 or thermocouple as the temperature sensing element. The packaging structure adopts a compact integrated structure in which the sensor and circuit are packaged in the one shell; the signal processing adopts a linearity better than 0.01%, extremely stable and efficient electronic adjustment technology; through the internal potentiometer, the zero point and range can be accurately adjusted.

RZ13 integrates sophisticated sensor components, excellent circuit technology, and advanced packaging manufacturing technology. It is an ideal product for medium-precision temperature measurement and control in various industrial and mining fields.

Product features:

l Reverse polarity protection and instantaneous over-current and over-voltage protection, comply EMI protection requirements.

l Through the internal potentiometer, the zero point and range can be accurately adjusted.

l The output signal has a variety of standard specifications such as: 4~20mA, Rs485 digital signal, HART protocol 4~20m can be connected to the display meter.

l Wide range of measurement.

l All stainless steel structure, protection grade IP65.

l Mutli-type of pressure connection.

l Intrinsically safe explosion-proof products meet the requirements of GB3836.4 standard and have obtained the explosion-proof certificate, and the explosion-proof mark is ExiaⅡCT6;

Classical applications:

u Temperature measurement of water, gas, oil, acid, alkali, salt, organic solvent etc.

u Temperature measurement and control system for industrial pipelines and containers.

u Temperature measurement of hydro-pneumatic equipment such as aircraft, loaders, compressors, etc.

Supply Ability

500 PCS / day

Lead Time

Quantity(Pieces) | 1 - 200 | 200 - 500 | >500 |

Est. Time(days) | 2~3 | 3~5 | 6~10 |

Technical Specifications

Functional parameters | |

Measurement range | -50℃…200℃ |

| Accuracy level | ±0.25%FS, ±0.5%FS,±1%FS |

Time constant | IV(<10 seconds), III(10~30 seconds), II(30~90 seconds), I(90~180seconds) Note: 1. Time constant means that when the medium’s temperature needs to be measured stepped from A to B, the time that the temperature-sensing element changed from A to [A+(B-A)x63.2%]; 2. The absolute value of (B-A) must meet: ≥70℃ 3. The temperature-sensing element’s response time is in connection with conduit’s material, diameter, wall thickness, insertion depth, installation mode, medium speed, etc. |

Ability of over pressure | 1.1~6 times of measurement range. (Varied from different measurement ranges) |

Working temperature | -40~80℃ |

Pressure withstand performance | 0.2MPa~100MPa (optional) |

Stability of range upper and lower limit | ≤(75% of maximum permissible errors corresponding to accuracy level) |

Electrical parameters | |

Power supply | 24VDC 12VDC(selected) |

Current load | <(U-10)/0.02Ω [U: power potential] |

Output signal | Two-line 4~20mA |

Dielectric strength | 500V no breakdown |

Insulation resistance | >500MΩ |

The effect of fluctuation of power supply on output | <0.003%FS/V |

Explosion-proof indication | Ex ia IIC T6 |

Requirements for electrical connection and wire diameter | Green terminals(wire diameter Φ4.5~Φ6.5mm) or stainless steel pipe joint(internal thread M16X1.5) |

Physical parameters | |

Applicable medium | Liquid and gas which would not react to the structure material (sensor and seal material) |

Sensor foundation material | Stainless steel (SS304), etc. |

Sensor seal material | NBR, fluororubber, tetrafluoroethylene, adhesive, etc. (no seal material for welding structure) |

Protection level | IP65, IP67, IP68 |

| Cable diameter | Φ4mm~Φ7.5mm |

Electrical interface | Right-angle elbow explosion-proof & waterproof connector or cable lead |

Surroundings parameters | |

Atmospheric pressure | 60~110kPa |

Environment humidity | ≤95%RH |

Storage temperature | -40~120℃ |

Vibration | 20gRMS, under condition 202kHz, difference <0.5%FS |

Impact | 100g, 10ms impact, difference <0.5%FS |

Electromagnetic / RF interference | Under the condition of 10~300MHz and 15V/m, the error is lower than 0.5%FS |

Outline Dimensions

Note:

1. Unit (mm)

2. Despite the difference of connection dimension, the outer dimension may be different; sensor length (L) and diameter (D) please consult manufacture when order.

Electrical Connections

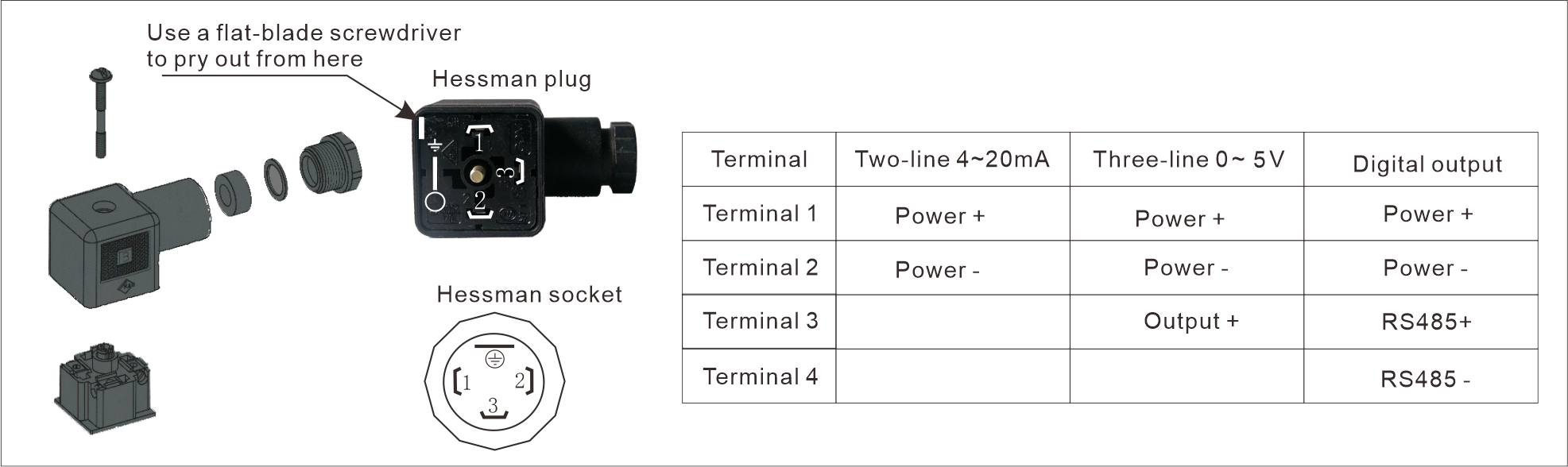

Hessman lug assembling and connection schematic diagram:

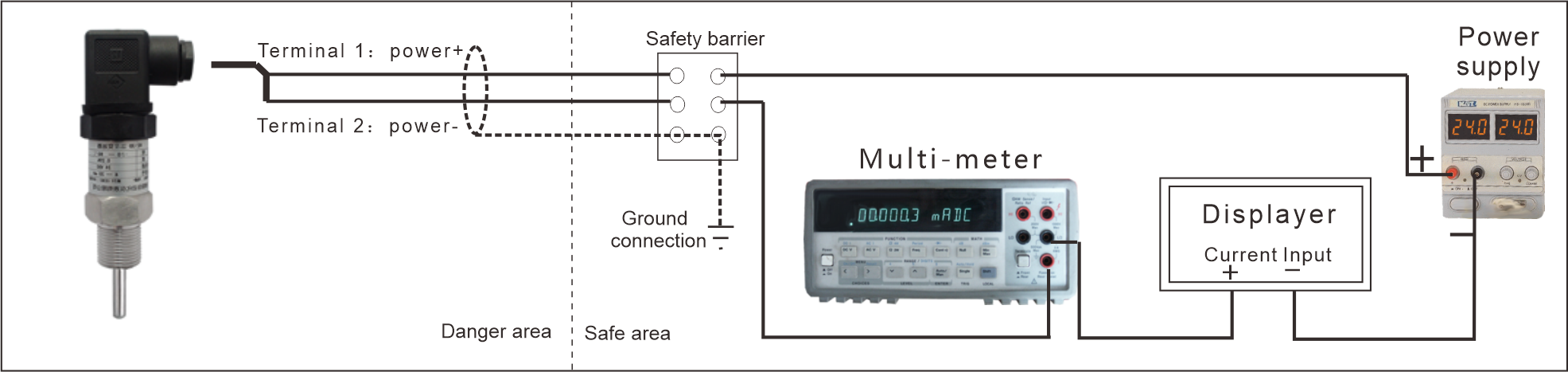

1: Schematic diagram for electrical connection of 2-line 4~20mA analog signal output:

2: Schematic diagram for electrical connection of 3-line 0/1-5V DC analog signal output:

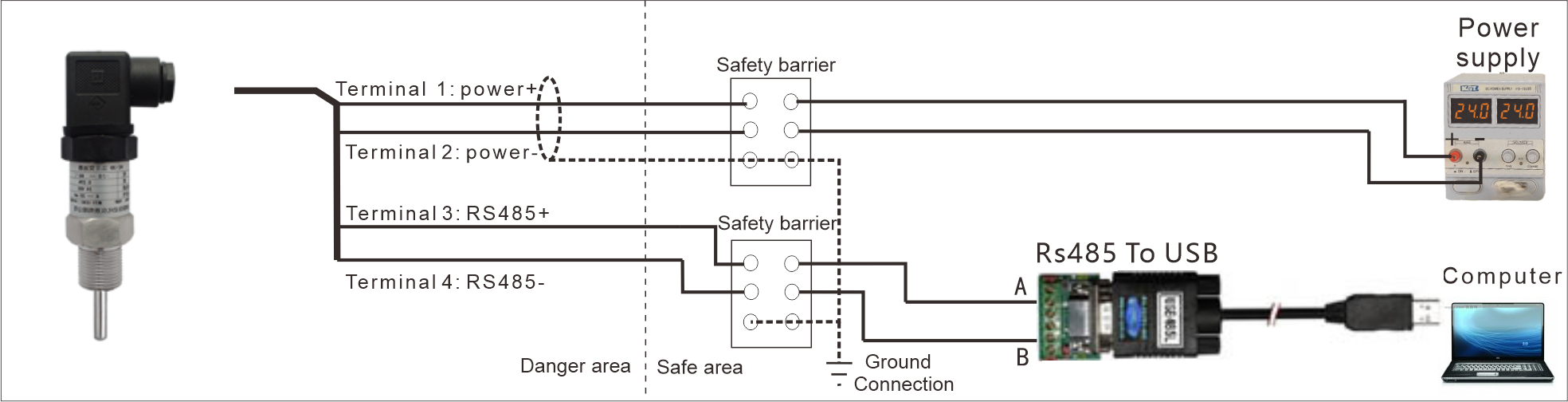

3: Schematic diagram for electrical connection of 4-line 485 digital signal output:

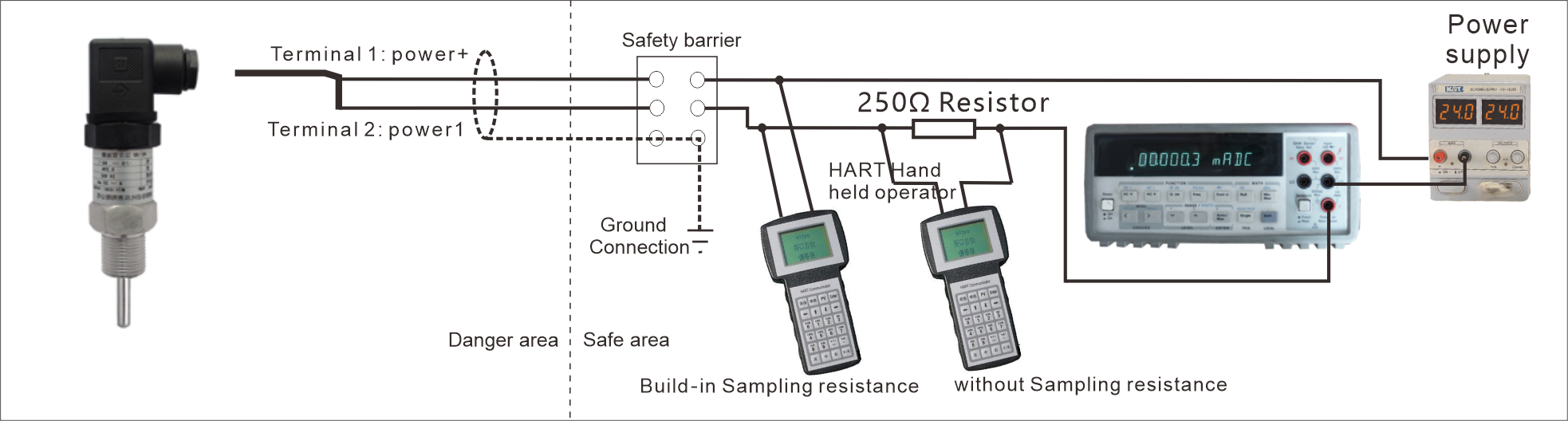

4: Schematic diagram for electrical connection of HART protocol liquid level transmitter:

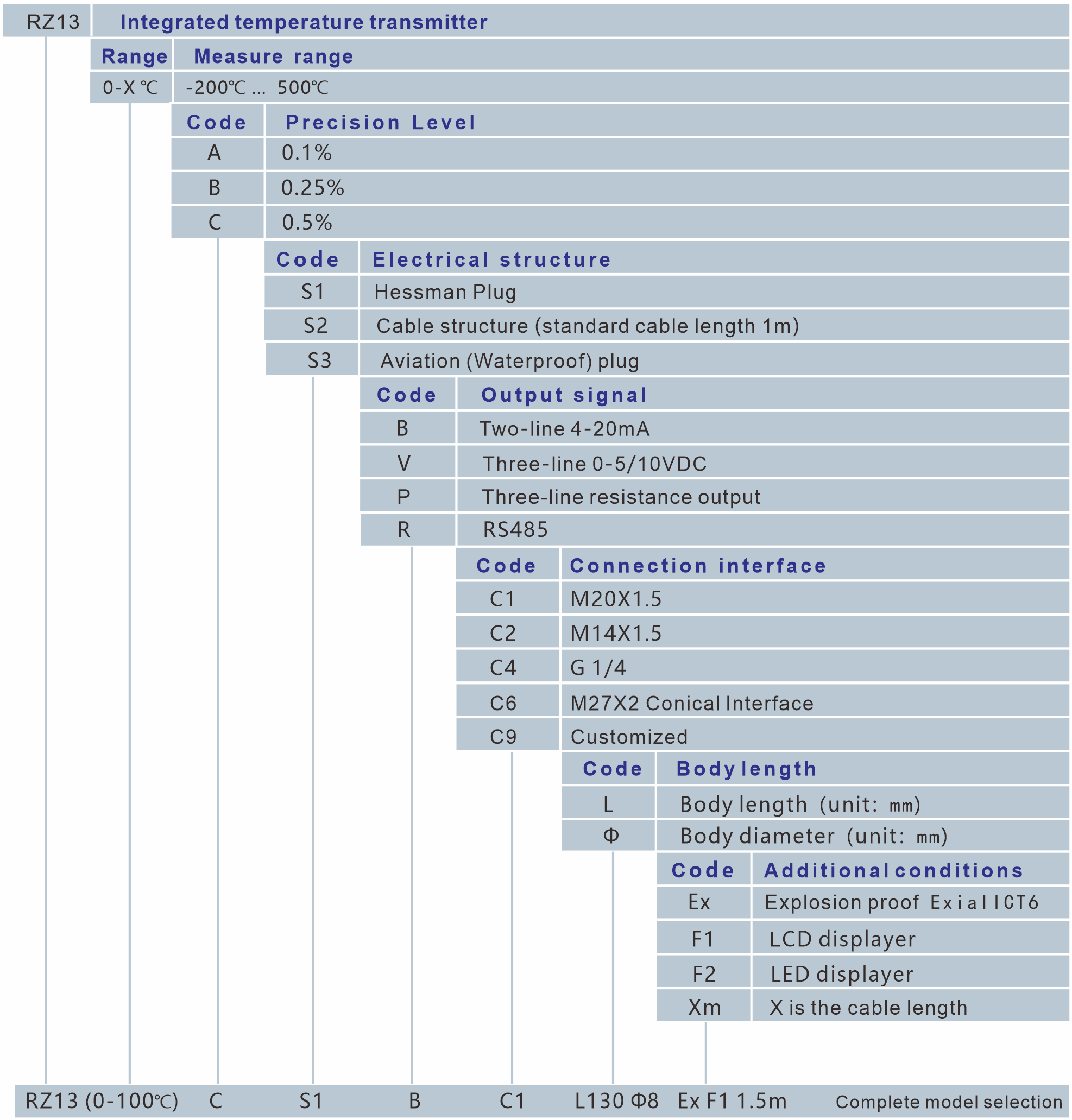

Selection Guide

Note:

1. Special requirements please consult our company and note in order document in detail.

2. The application medium must be compatible with the selected product.

3. Please note that the explosion-proof product does not include the displayer.

4. If order transmitter with LCD or LED meter, power supply cannot be lower than 15V DC.

5. Customized connector type and size can be noted beside the selection model.